| Chevrolet - GMPP FAST BURN CYLINDER HEAD |

|

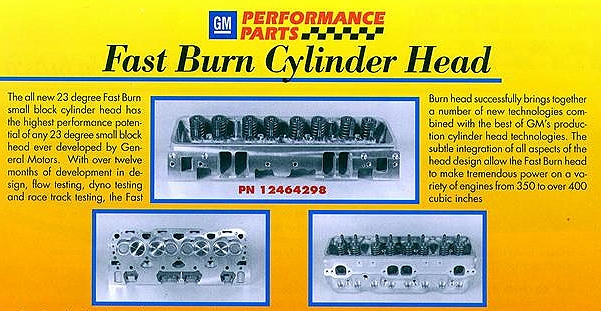

The biggest news to come from GM Performance Parts in recent history is the all new Fast

Burn cylinder head for small-block Chevy engines. This head incorporates more technology,

features and performance potential than any previously designed GM 23° head. Key - gmhead |

|||||||||||||

| We are updating all of our Chevrolet Parts and GM Performance Parts pricings and availability. There is lots of information here regarding your favorite Chevy projects or custom engines. |

| ||||||||||||

| WEB SITE NAVIGATION INFORMATION |

| If you have you just came from a search engine and are stuck with no navigation, turn on Java Scripts in your Web browser, reload the page, then you can turn off Java Scripts again. Also, people using Internet Explorer have to use the pull down tab next to the back button to return to a search engine. More information on this is on our help page. |

| GM and Chevrolet part prices are in the Price & Parts search. Keys are to be used with the Price & Parts Search. Enter a Key, part number, GM, SC, or a key word, like 502, into the Price & Parts search to see if we have it on our site. Use GM for a list of both GM and GMPP parts. Use SC for a list of all Chevrolet exclusive parts. Aftermarket company prices are on downloadable Price Sheets or on their pages. The Page Search is for searching the pages of our Web site. More information on this is on our help page. |

| CYLINDER HEAD NAVIGATION |

| GMPP ALUMINUM FAST BURN HEAD ASSEMBLY |

|

This head can be used on any 1958-99 283-400ci small block Chevrolet V8 engine with conventional

water flow design, but this head cannot be used on any LT1, LT2, or LS1 engines that are designed with reverse water

flow. P/N 12464298 |

|

|

Technical Note:

Use intake manifold P/N 12496820, P/N 12366573,

12496822, or 10051103 with the Fast Burn cylinder head. Use intake manifold gasket

P/N 12529094 and eight attaching bolts P/N 12550027. Use Fel-Pro exhaust gasket

P/N 1470 for these Fast Burn heads (some trimming may be required for your application.

This head includes intake valves P/N 12555331, exhaust valves P/N 12551313, valve

spring cap P/N 10212808, and valve springs P/N 12551483. |

| EXCERPTS FROM SPEED READING ARTICLE BY GARRY PENN FROM GMPP |

| Webmaster’s note: The flow numbers for the Fast Burn heads in the table below were derived from a prototype head and do not reflect the correct values for a production head. We never did get the official flow numbers from GM, so now that the new Fast Burn head version is out, we had both of them flow tested ourselves. At the bottom of this page is a table with the results of the flow test. |

| Intake Flow Comparison | |||||||

| Valve Lift | GMPP Fast Burn |

Edelbrock Performer |

Dart Conquest 200 |

Brodix Track-1 |

GM Vortec L31 |

World Sportsman |

|

| 0.100” | 62 | 66 | 60 | 60 | 58 | 65 | |

| 0.200” | 136 | 135 | 124 | 130 | 114 | 121 | |

| 0.300” | 187 | 186 | 180 | 178 | 173 | 177 | |

| 0.400” | 232 | 215 | 221 | 223 | 216 | 210 | |

| 0.500” | 266 | 220 | 254 | 256 | 225 | 212 | |

| 0.600” | 275 | 222 | 261 | 259 | 222 | 225 | |

| Exhaust Flow Comparison | |||||||

| Valve Lift | GMPP Fast Burn |

Edelbrock Performer |

Dart Conquest 200 |

Brodix Track-1 |

GM Vortec L31 |

World Sportsman |

|

| 0.100” | 55 | 55 | 54 | 50 | 43 | 48 | |

| 0.200” | 104 | 103 | 98 | 103 | 88 | 95 | |

| 0.300” | 133 | 135 | 130 | 142 | 125 | 120 | |

| 0.400” | 158 | 151 | 156 | 166 | 143 | 138 | |

| 0.500” | 180 | 165 | 168 | 175 | 149 | 143 | |

| 0.600” | 193 | 169 | 175 | 183 | 152 | 152 | |

|

The biggest news to come from GM Performance Parts in recent history is the all new Fast

Burn cylinder head for small-block Chevy engines. This head incorporates more technology,

features and performance potential than any previously designed GM 23° head. We have

completed the development and the validation of the head and are in the process now of

building the production tooling. A small number of these heads will be built from

prototype tooling, these heads will be used on the Limited Edition ZZ430 Crate Engine. Some of the details about the Fast Burn head are as follows, and I'm sure that once you've read this you'll be as exited about this new head as we are! The all new 23° Fast Burn small-block cylinder head has the highest performance potential of any 23° small-block head ever developed by General Motors. With over twelve months of development in design, flow testing, dyno testing and race track testing, the Fast Burn head successfully brings together a number of new technologies. The subtle integration of all aspects of the head design allow the Fast Burn head to make tremendous power on a variety of engines from 350 to over 400 cubic inches. The name Fast Burn refers to the head’s ability to quickly and completely burn the air/ fuel mixture, making higher cylinder pressures and therefore more power. The shape of the combustion chamber has been carefully and painstakingly designed to accomplish this Fast Burn with flat top pistons. Therefore, flat top pistons are recommended with this cylinder head. Further, it is not recommended that the combustion chamber be modified or re-shaped, as this is very likely to decrease the efficiency of the chamber. The Fast Burn head is designed with a .400 deck, which provides the necessary structure for the head. This revolutionary approach to head design allows a great deal of material to be removed from other portions of the head, allowing for considerably larger ports and water jacketing. The substantial deck also provides unsurpassed clamping force for cylinder head gasket retention. The super rigid .400 deck thickness can be machined down to .340 safely for all-out performance applications and higher compression. Milling beyond .080 may increase the possibility of structural failure in long tem use in extreme performance applications, leading to possible head gasket seepage and other problems. Other ways to adjust compression ratio with the Fast Burn head include top of piston design and piston installed height. Unlike the GM Performance Parts Bow Tie heads, and most aftermarket performance heads, the Fast Burn head requires no additional porting for maximum performance. In the past, the industry has added material to heads to allow substantial porting. The downside to this is minimized water jacketing, poor out-of-the-box performance and significant additional cost to performance enthusiasts. The Fast Burn head utilizes GM Performance Parts' Cast-Ported technology. Cast-Ported simply means that throughout or developmental process as incremental improvements in flow, combustion and cylinder fill were identified, those improvements were incorporated in the casting and machining tooling. The end result is a cylinder head that achieves maximum performance out-of-the-box. While additional porting of the Fast Burn head is not recommended, light sanding to remove minor casting imperfections and polishing of combustion chambers and exhaust ports is acceptable. All Fast Burn heads are CNC machined to exacting tolerances, thus eliminating the need for blue printing of machined tolerances. The result of this is cost savings to performance enthusiasts and unsurpassed out-of-the-box performance. The Fast Burn head has taller than typical rocker cover rails, providing exceptional clearance for rocker arms and valve train supports typically used in all out performance applications. Additionally, the tall rocker cover rails reduce oil loss at the valve cover gasket by placing the gasket higher, out of most of the standing oil that occurs at high RPM applications. The rocker rails are CNC machined for superior rocker cover gasket sealing. Front head faces are drilled and tapped for typical accessory drive bracketry. Provisions are drilled and tapped for plug wire retainers above the exhaust port faces. The Fast Burn head accepts both center bolt and early style four bolt flange mount valve covers. No valve cover adapters are required. Cast-Porting allows for larger water jackets for superior cooling. Signature etched with GM Performance Parts logo. Intake manifold mating surfaces are drilled and tapped for both Vortec and conventional raised port style manifolds. D shaped 78cc exhaust port and runners provide exceptional flow for applications well in excess of 500 horsepower. Raised runner (.240 higher than conventional 23° head) intake ports with 210cc ports and runners provide exceptional flow for applications well in excess of 500 horsepower. Raising the top of the intake ports provides a better “line-of-sight” through the port and onto the back side of the intake valves. The 62cc fast burn combustion chambers are the most efficient combustion chambers ever to be incorporated on a GM Performance Parts cylinder head. Their Fast Burn efficiency produces higher cylinder pressures by burning more of the available fuel before the piston starts its power stroke downward. Additionally, by more completely using the available fuel, the head ensures that an engine is producing more power for a given quantity of fuel. The Fast Burn head’s specially designed valve seats will accommodate up to 2.02 intake valves and 1.600 exhaust valves. Their design also provides superior structural characteristics. The 2.00 hollow stem lightweight intake valves are utilized to provide exceptional flow and intake charge velocity. Their light weight makes them suitable for sustained high RPM applications as well as reducing loads on valve springs, rocker arms, push rods, roller lifters and camshaft. The 1.56” sodium filled lightweight exhaust valves have all the same great benefits of the hollow stem intake valves. In addition, they are able to perform in extremely high-temperature performance applications. Light weight valve spring retainers combined with light weight valves helps ensure long-term high RPM durability. Screw-in 3/8” rocker studs are used., and accept most available self aligning style roller rocker arms. Uses all conventional low cost readily available 23° self aligning rocker arms and valvetrain supports and hardware. GM Performance Parts attention to detail in the Fast Burn head tooling assures super clean and accurate castings. This cylinder head is a bolt-on 40 horsepower increase when used on our ZZ4 crate engine. With appropriate camshaft selection, a single plane intake manifold and a 750 cfm carburetor, a ZZ4 crate engine is capable of producing 500+ horsepower. When tested on a 383 cubic inch small-block engine with 9.8 to 1 compression ratio and .540 lift roller cam, single plane intake manifold and 750 cfm Holley carburetor, the Fast Burn heads produced 497 horsepower at an incredibly low 5800 RPM. Total ignition timing to be used on a Fast Burn head engine will vary based on a number of factors. However in our extensive dyno testing most configurations made the most power with 34° of total timing. A pair of prototype Fast Burn heads successfully completed the 1998 Sebring twelve hour race with no signs of fatigue or problems of any nature. In fact, when run on a dyno after the race the engine produced ten more horsepower than it did after initial assembly and break-in. In testing on a Superflow 600 flow bench at 28 H²0, the Fast Burn head performed as indicated in the chart below*. (*above) [Note from the Webmaster: This was a prototype Fast Burn head used to obtain these flow numbers and the numbers do not reflect the flow numbers obtained from a production Fast Burn head.] Technical Note:

For comparison purposes all heads were fitted with 2.02 intake and 1.60 exhaust valves,

except the Brodix Track-1, which was delivered with 2.080 intake valves, the Vortec, which had

1.94 intake and 1.50 exhaust valves, and the Fast Burn heads which used 2.00 intake and 1.56

exhaust valves. All flow ratings in CFM. Color red indicates highest flow at that valve lift. |

| FLOWS RESULTS: ORIGNINAL HEADS - VS - NEW HEADS |

| Webmaster’s note: Chevrolet flow tested the new and old GMPP Fast Burn heads for comparison. The results for the other heads below were copied from the charts above for reference. Since our test where not done with the same setup as GM used in their test, you can’t make a direct correlation with the results of the other heads. You can get an idea of how the new Fast Burn heads stack up to the competition though. The following two charts are only meant to show the differences between the old and new Fast Burn heads and nothing else. |

| Intake Flow Comparison | |||||||

| Valve Lift | Old GMPP Fast Burn |

New GMPP Fast Burn |

Edelbrock Performer |

Dart Conquest 200 |

Brodix Track-1 |

GM Vortec L31 |

World Sportsman |

| 0.050” | 28 | 30 | |||||

| 0.100” | 62 | 61 | 66 | 60 | 60 | 58 | 65 |

| 0.150” | 100 | 95 | |||||

| 0.200” | 131 | 126 | 135 | 124 | 130 | 114 | 121 |

| 0.250” | 151 | 156 | |||||

| 0.300” | 170 | 180 | 186 | 180 | 178 | 173 | 177 |

| 0.350” | 187 | 201 | |||||

| 0.400” | 200 | 221 | 215 | 221 | 223 | 216 | 210 |

| 0.450” | 211 | 238 | |||||

| 0.500” | 220 | 243 | 220 | 254 | 256 | 225 | 212 |

| 0.550” | 227 | 239 | |||||

| 0.600” | 233 | 238 | 222 | 261 | 259 | 222 | 225 |

| Exhaust Flow Comparison | |||||||

| Valve Lift | Old GMPP Fast Burn |

New GMPP Fast Burn |

Edelbrock Performer |

Dart Conquest 200 |

Brodix Track-1 |

GM Vortec L31 |

World Sportsman |

| 0.050” | 21 | 23 | |||||

| 0.100” | 39 | 53 | 55 | 54 | 50 | 43 | 48 |

| 0.150” | 62 | 80 | |||||

| 0.200” | 86 | 107 | 103 | 98 | 103 | 88 | 95 |

| 0.250” | 109 | 124 | |||||

| 0.300” | 126 | 140 | 135 | 130 | 142 | 125 | 120 |

| 0.350” | 141 | 155 | |||||

| 0.400” | 154 | 167 | 151 | 156 | 166 | 143 | 138 |

| 0.450” | 165 | 173 | |||||

| 0.500” | 174 | 178 | 165 | 168 | 175 | 149 | 143 |

| 0.550” | 180 | 181 | |||||

| 0.600” | 186 | 184 | 169 | 175 | 183 | 152 | 152 |

| «-- GO BACK TO 1998 GMPP UPDATE PAGE |