| Chevrolet - HIGH PERFORMANCE 4L60 4-SPEED AUTOMATIC TRANSMISSION INSTRUCTIONS |

|

This sophisticated four-speed is GM’s first (remanufactured), over-the-counter automatic transmission assembly for high-performance vehicles. This page supplies information to help with the installation of this transmission. Key - gmtransmission |

|||||||||||||

| |||||||||||||

| WEB SITE NAVIGATION INFORMATION |

| If you have you just came from a search engine and are stuck with no navigation, turn on Java Scripts in your Web browser, reload the page, then you can turn off Java Scripts again. Also, people using Internet Explorer have to use the pull down tab next to the back button to return to a search engine. More information on this is on our help page. |

| GM and Chevrolet part prices are in the Price & Parts search. Keys are to be used with the Price & Parts Search. Enter a Key, part number, GM, SC, or a key word, like 502, into the Price & Parts search to see if we have it on our site. Use GM for a list of both GM and GMPP parts. Use SC for a list of all Chevrolet exclusive parts. Aftermarket company prices are on downloadable Price Sheets or on their pages. The Page Search is for searching the pages of our Web site. More information on this is on our help page. |

| GM AND GMPP TRANSMISSIONS NAVIGATION |

| GMPP 4L60 TRANSMISSION INSTALLATION INSTRUCTIONS |

|

Important! Read and follow these instructions! In order to achieve proper operation of this transmission in your vehicle, it may be necessary to make adjustments and calibration changes described in these instructions. Failure to perform these adjustments and calibrations may result in poor vehicle performance and possible transmission damage. Additional modifications may be required to install this assembly in a vehicle not originally equipped with a 4L60 transmission. This instruction sheet is intended as a supplement to General Motors service manuals, which describe service procedures in detail. It is not intended to replace comprehensive service manuals and parts catalogs which cover GM transmissions and components. Service manuals for GM vehicles are available from: Helm, Inc. P.O. Box O7130 Detroit, MI 48207 Please read this entire instruction sheet before starting work to familiarize yourself with the installation procedure. Observe all safety precautions and warnings in GM service manuals when installing the 4L60 transmission assembly. Wear eye protection and appropriate protective clothing. Support the vehicle securely with jackstands when working under or around it. Use only the proper tools. Exercise caution when working with flammable, corrosive, and hazardous materials. Some procedures require special equipment and skills. If you do not have the appropriate training, expertise, and tools to perform any part of this installation safely, this work should be done by a professional. Technical Features

The 4L60

four-speed automatic overdrive transmission assembly is General Motor’s first

over-the-counter automatic transmission assembly designed specifically for high-performance

vehicles. It has a 3.06:1 first gear ratio that provides quick acceleration, and

a 0.70:1 overdriven fourth gear and lock-up torque converter that reduce engine

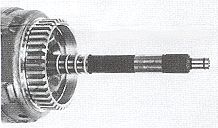

speed and enhance fuel economy during highway cruising.This heavy-duty transmission is assembled with the following premium components:  • Turbine input shaft shot-peened to improve durability.  • High-strength steel 298mm (11-3/4„) diameter torque converter with furnace-brazed fins. • Lock-up converter clutch rated for 350 ft.-lbs. torque. |

|

|||||||

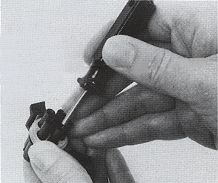

Wiring Harness Using the terminal removal tool supplied with the transmission assembly, remove all of the wires from the five-pin TCC connector wiring harness that is supplied with the transmission. Then transfer the wires from the vehicle’s four-pin TCC connector to the five-pin connector. Remove the wire from the four-pin TCC connector marked “A” and insert it in the “A” terminal of the five-pin TCC connector. Repeat this procedure for the “B”, “C”, and “D” terminals, transfer the wires from the four-pin connector to the same respective terminals on the five-pin connector. (Remove the plug in the five-pin connector’s “C” terminal before transferring the wire.) The fifth terminal “E” is not used in this conversion; do not connect a wire to it.  The 4L60 transmission assembly uses a five-pin TCC connector (right). A pre-1993 wiring harness with a four-pin TCC connector (left) can be modified to work with the 4L60 transmission.  Transfer the wires from the four-pin connector to the respective five-pin connector (“A” to “A”, “B” to “B”, etc.). The fifth “E” terminal is not used. Non-Computer-Controlled Vehicles:

When installing a 4L60 transmission in a non-computer-controlled vehicle, connect the

supplied wiring harness for the

4L60 transmission’s five-pin TCC connector to a 12-volt power source through a stop lamp/torque converter switch

(P/N 25524845) to allow disengagement of the converter clutch during brake application. (Note: This circuit

should be “live” only when the ignition is switched on.) This wiring system will apply the torque converter clutch

whenever the transmission is in fourth gear. Do not change the fourth gear clutch switch when installing the 4L60

transmission in a non-computer-controlled vehicle.

|

|

|||||||

Chevrolet’s Additional Installation Information |