| Chevrolet - CNC GEN V SHORT DECK (9.800”) PRO STOCK BOW TIE BARE BLOCK |

|

|

|||||||||||||||

| WEB SITE NAVIGATION |

|

GM & SC HOLLEY AFR |

EDELBROCK FLUIDAMPR R&M |

SCAT MSD |

DEMON WORLD |

HUGHES TREMEC |

RICHMOND PROFORM |

| DESCRIPTION |

|

|

|

|

|

CNC Machined Short Deck Racing Bow Tie Pro Stock Bare Block |

|

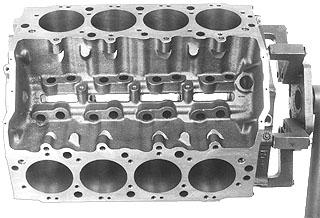

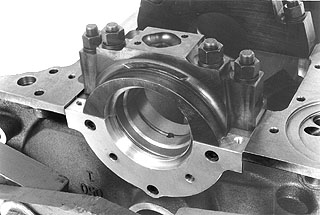

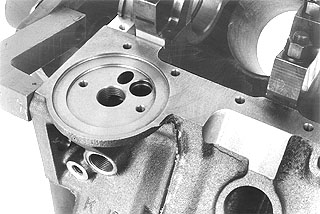

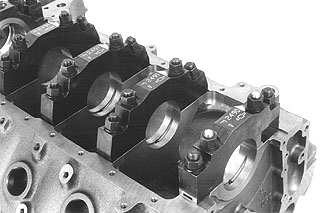

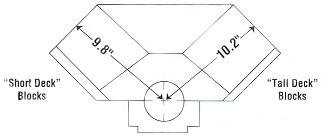

P/N 24502500 This bare block is the same as P/N 10185049 except it has all 8620 steel main caps and all are CNC machined with standard 9.80” deck. The Gen V CNC-machined race prepared short deck Bow Tie block starts with the same casting used in the P/N 10185049 production machined block. All of these blocks feature blind head and accessory mounting bolt holes, a deck configuration that enables the use of any big block Chevrolet cylinder head, and cylinder bores that may be bored to 4.600” diameter while maintaining a minimum wall thickness of .250”. In addition, the new castings design improves engine block life and build ability of the previous generation of Mark IV big block Chevrolet blocks. CNC machined race prepared Bow Tie blocks differ from the production machined Gen V Bow Tie versions in certain areas. CNC race prepared blocks start from a raw casting and are not “conversions” and use a rear seal adapter to convert the Gen V production type one piece rear main seal to a Mark IV type two-piece seal that facilitates the use of a widely available Mark IV style crankshaft. In addition, 8620 steel bearing caps are put in all locations to further increase the integrity of the bottom end. The intermediate caps also feature 16° splayed outer bolts which anchor the caps into the strongest section of the block and prevent bearing cap movement under high loads. Bow tie race prepared, as well as production GEN V blocks use priority main style oiling, in which the oil flows from the main gallery near the cam, oiling the cam via a small hole, and directly to the main journals. The main oil gallery on these blocks is relocated and enlarged to 9/16” diameter to allow increase oil flow through the block. The oil cooler provisions found on all Gen V production machined blocks is eliminated so that plugging of this boss is not required when prepared for a racing style oiling system. CNC race prepared Bow Tie blocks have inner head bolt bosses which allow better retention of cylinder heads in high horsepower applications due to cylinder head “lifting” from the block do to high cylinder pressures. The tall and short deck race prepared blocks weigh 288 and 278 pounds respectively which is at least 12 pounds lighter than imitation Bow Tie aftermarket blocks. Casting P/N 24502504. The Gen V Pro Stock Bow Tie bare block has been the standard for the serious pro stock or boat racer. The Bow Tie block has siamesed cylinder walls and a two-piece rear main oil seal. Some of the standard features of this block are: extra thick deck surfaces with blind tapped head bolt holes, priority main oiling, no mechanical fuel pump boss, improved coolant flow around the No. 1 cylinder, and inner head bolt bosses. This block also has steel four-bolt splayed bearing caps. Mark IV style cylinder heads can be used on this block. Technical Notes: The Gen V block does not have provisions for a mechanical fuel pump, however, an electrical pump can be substituted in most applications. Many internal components are interchangeable between Mark IV and Gen V engines, including pistons, connecting rods, camshafts, timing sets, and lifters. External accessories such as water pumps, distributors, intake manifolds, and exhaust exhaust manifolds are also interchangeable. Chevrolet’s new cast iron Gen V Bow Tie block short deck casting number 10185050 is engineered for maximum-effort racing engines. The “short-deck” (passenger car) block has a 9.80” crankshaft centerline-to-deck dimension. Heavy-duty Gen V blocks can be identified by the Bow Tie logos cast beneath the deck surfaces. The water jacket plugs in all Gen V blocks are centered in raised bosses; the 1.625” diameter soft plugs are interchangeable with small-block and V6/90° Chevrolet engines. The Gen V Bow Tie block uses a two piece crankshaft assembly, seal, and oil pan reminiscent of the Mark IV block. The Bow Tie block differs from production Gen V blocks, which used a one piece seal, and improves the availability of large stroke crankshafts. When using a Mark IV crankshaft, engine builders should remember that the crank is externally balanced and therefore should use only Mark IV type flywheels and balancers. The Gen V Bow Tie block is equipped with four-bolt 8620 steel main bearing caps with 16° splayed outer bolt holes on the three inner caps. The front and rear caps utilize four straight bolt 8620 steel caps. The main cap has provisions for wet-sump style oil systems. Like previous Bow Tie big-blocks, the Gen V heavy-duty block has extra-thick siamesed cylinder walls. Water passages between adjacent cylinders are eliminated to produce extremely rigid barrels that resist distortion and enhance piston ring sealing. The cylinders are bored to 4.250” diameter at the factory. The cylinder barrels are cast with a slightly oval-shape to minimize core float and ensure consistent and maximum wall thickness for all cylinders. The maximum recommended cylinder bore is 4.600”, which results in a minimum cylinder wall thickness of .250”. For maximum effort competition engines, Gen V Bow Tie blocks have inner head bolt bosses cast in, to allow additional cylinder head retention. This prevents cylinder head “lifting” when used in high pressure applications. The coolant passages in the Gen V Bow Tie block differ from the passages in both Mark IV and production Gen V versions. Production Gen V blocks have irregular shaped coolant holes in the deck surface; these holes are small and round in Bow Tie blocks. These smaller openings in the deck surfaces improve the integrity of the head gasket seal under high cylinder pressures and reinforce the tops of the cylinder bores to reduce distortion. Competition engine builders can block or resize these round holes by installing threaded pipe plugs. The coolant holes in the Gen V Bow Tie block are smaller than the holes in a Mark IV Bow Tie block. In addition, the hole between the two middle cylinders has been reduced in size and relocated farther away from the lifter valley to improve the head gasket seal. Gen V Bow Tie blocks have an additional hole at the front of the cylinder case. This passage is a vent hole that allows gas to escape during the casting process. If this hole is not plugged, water entering the block from the water pump can “short circuit” the cooling system by bypassing the block and cylinder head coolant jackets and returning directly to the radiator. These vent holes should be blocked on both deck surfaces to force the coolant to circulate through the engine. Gen V head gaskets do not have coolant holes in this position, and will effectively block the passages. The holes can also be plugged by reaming the cast holes to 3/4” diameter and inserting soft plugs. Use a length of 5/8” diameter bar stock to drive the plugs into the block so they are flush with (or below) the deck surfaces. All head bolt holes in the Gen V Bow Tie block are blind-tapped. No sealant is necessary on the head bolt threads because the holes do not penetrate the water jacket. Lightly lubricate the threads to produce accurate torque readings when tightening the head bolts. Both Mark IV and Gen V cylinder heads can be installed on Gen V Bow Tie blocks. However, there are differences in the size and location of coolant passages in the cylinder heads and head gaskets used with Mark IV and Gen V big-blocks. The Gen V head gasket blocks the large coolant passage at the cylinder head; a Mark IV gasket leaves this passage open. Mark IV head gaskets may be used on a Gen V block if the coolant passages in the front of the decks are plugged. Due to changes in the water passages, there is a possibility leaks into the lifter valley if Gen V head gaskets are used on Mark IV cylinder heads. A Mark IV head gasket may not seal the larger coolant holes in the Gen V cylinder heads properly. To forestall sealing problems, Mark IV and Gen V head gaskets should be used only with their respective cylinder heads. The lifter bosses in the Gen V Bow Tie block are larger than the bosses in Mark IV Bow Tie and production Gen V blocks. These oversized bosses allow an engine builder to install larger diameter lifters after boring out the tappet bores. The lifters can also be relocated to optimize valvetrain geometry by offset boring of the lifter holes. The front bulkhead of a Gen V Bow Tie block is moved forward .300” compared to a production Gen V Bow Tie block. This change improves coolant flow around the number one cylinder in the Bow Tie block, which has larger cylinder barrels than a production casting. Both single-row and double-row timing chains will clear this bulkhead. However, if a Jesel belt-type timing system is installed on a Gen V Bow Tie block, the back of the Jesel aluminum cover must be machined for clearance. The short deck Gen V Bow Tie block weights 278 pounds, which is at least 12 pounds lighter than imitation aftermarket blocks. Oiling System The main oil gallery in all Gen V blocks is located alongside the camshaft tunnel. This oil gallery location allowed the installation of splayed-bolt main bearing caps and the ability to machine the oil pan rails for additional crankshaft clearance without the risk of breaking into the main oil passage, which was a concern on Mark IV blocks. The main oil gallery diameter of Gen V Bow Tie blocks is 9/16”. The Gen V Bow Tie block has a “priority main” oiling system, which was developed for use in the legendary ZL-1 aluminum big-block. Drilled passages carry oil directly from the main oil gallery to the front four main bearings. (Oil for the rear main bearing is routed routed from the oil filter outlet.) Oil is supplied to the camshaft bearings in a Gen V big-block through passages drilled from the lifter valley. These passages intersect the cam bearing bore tangentially, opening an oval “window” approximately 1/2” long and 1/4” wide. When installing camshaft bearings in a Gen V block, the oil hole in the bearing insert should be at 2 o’clock position when viewed from the front of the block. The main oil gallery in a Gen V Bow Tie block is the same size (7/16” diameter) and in the same position as the main oil gallery in a production Gen V block. Material has been added to the Bow Tie casting to allow engine builders to enlarge this passage. However, if the diameter os the main gallery is increased, its centerline must be relocated to prevent breaking into the lifter bores. The hone over-travel relief’s at the bottoms of the cylinder bores are squared-off to maximize bottom end strength. The main bearing bulkheads are fully machined. The Gen V Bow Tie block has provisions for a dry sump oil inlet line. The oil passage at the rear of the block above the bellhousing flange can be drilled out to the main oil gallery and threaded for a 1/2” NPT (National Pipe Thread) pipe fitting. Oil from the pressure stage of the dry sump oil pump can be pumped directly into the main oil gallery through this hole. The integral connections production Gen V blocks have for external oil coolers are omitted on Gen V Bow Tie blocks so that plugging of these passages is not required. in addition, the boss for the integral connections has been removed from the block to reduce weight and improve assembly time. Material was added to them bottoms of the cylinder barrels in Gen V Bow Tie blocks to increase strength and to accommodate large cylinder bore diameters. In some instances, the bottom of the number eight cylinder barrel may interfere with the distributor gear. (This is not a problem in production Gen V blocks, which have smaller cylinder barrels.) Any interference can be easily corrected by chamfering the bottom of the distributor gear or grinding additional clearance in the block. Some aftermarket distributors have O-rings on the distributor shaft that seal the passenger’s side lifter oil gallery. Because of the size of the camshaft tunnel in the Gen V block, these O-rings may not actually seal the distributor hole. This can be checked by pre-assembling the engine and verifying the position of the O-rings in relation to the distributor hole. The position of the distributor in the block can be adjusted if necessary by machining the distributor pad on the intake manifold (to lower the distributor) or adding spacers between the distributor and manifold (to raise the distributor). |

|

| SPECIFICATIONS: |

|

Block Material: Cylinder Wall Type: Deck Height: Cylinder Bore Range: Cap Bolts: Cap Bolt Orientation: Cap Material: |

Cast Iron Siamesed 9.800” 4.250-4.600” 4 Bolt Splayed 16 degree 8620 Steel |

Crankshaft Journal Dia.: Oil Sump Type: Crankshaft Seal: Design Max. Stroke: Weight (bare): Oil Pan Style: Intended Usage: Fuel Pump Boss: |

2.75” Wet 2 Piece Mark IV 4.600” 278 lbs. Mark IV Professional Competition None |

|

Special Features: Race Prepared Machining, Valley Head Bolt Bosses, and Enlarged Main Oil Gallery |

|||